- What is a Catalytic Converter Temperature Test

- Perform a Catalytic Converter Temperature Test

- Causes of High Catalytic Converter Temperatures

- Benefits of Regularly Testing the Catalytic Converter

- Repair a Catalytic Converter Temperature Sensor

- Impact of Exhaust System Modifications

- Engine Load and Catalyst Temperatures

- Maintaining Optimal Catalyst Performance

- Different Driving Conditions on Catalyst Performance

What is a Catalytic Converter Temperature Test and Why is it Important?

A catalytic converter temperature test is a diagnostic procedure used to measure the temperature of the catalytic converter. This test is important because it helps to identify any potential problems with the converter, such as clogging or damage to the catalytic converter.

The temperature of the catalytic converter should be within a certain range for it to function properly and efficiently. If the temperature is too high, this can indicate that there is an issue with the converter that needs to be addressed. So, be mindful of the symptoms of a clogged catalytic converter.

Conversely, if the temperature is too low, this could mean that there are issues with fuel delivery or other components of the exhaust system. By performing a catalytic converter temperature test, technicians can quickly diagnose and repair any issues before they become more serious and costly problems.

How to Perform a Catalytic Converter Temperature Test

A catalytic converter temperature test is an important part of maintaining a vehicle’s emissions system. The catalytic converter helps reduce the number of pollutants released into the atmosphere by converting harmful gases into less harmful ones.

It is important to ensure that the catalytic converter is operating at its optimal temperature to maximize its efficiency and effectiveness. This article will explain how to perform a catalytic converter temperature test.

- The first step in performing a catalytic converter temperature test is to locate the exhaust manifold on your vehicle. This can usually be found near the engine block, and it will have several pipes connected to it that lead out from underneath your car. Once you have located the exhaust manifold, you should attach an infrared thermometer probe directly onto one of these pipes using a clamp or other secure method.

- Next, start up your vehicle and allow it to idle for several minutes so that it reaches normal operating temperatures. Then, take readings from each pipe connected to the exhaust manifold with your infrared thermometer probe until you find one that has higher than normal temperatures (usually around 500-600 degrees Fahrenheit). This indicates that this pipe contains hot exhaust gases passing through it which means this pipe likely contains your vehicle’s catalytic converter.

- Once you have identified which pipe contains your vehicle’s catalytic converter, take multiple readings from this pipe over time while monitoring any changes in temperature levels as well as any fluctuations or spikes in temperatures over time (which could indicate potential problems with your emissions system). If all readings are within normal ranges then there are no issues with your emissions system and no further action needs to be taken; however, if any readings are outside of normal ranges then further investigation may be necessary such as replacing or repairing components within the emissions system or having a professional inspect and diagnose any potential issues with more accuracy and precision than what can be done at home by yourself without specialized tools or knowledge about automotive systems.

By following these steps, you can easily perform a basic yet effective diagnostic check on your vehicle’s emission control system by testing its catalyst’s operating temperatures using an infrared thermometer probe attached directly to one of its pipes connected to the exhaust manifold located near its engine block area underneath its bodywork panels/coverings/shields, etc.

Doing so regularly will help ensure optimal performance from both components while also helping reduce overall pollutant output levels released into our environment due to their combined efforts working together efficiently towards achieving cleaner air quality standards for us all (not to mention using a good catalytic converter cleaner to unclog it).

Common Causes of High Catalytic Converter Temperatures

The catalytic converter is an important component of a vehicle’s exhaust system, as it helps to reduce the number of harmful emissions released into the atmosphere. Unfortunately, high temperatures in the catalytic converter can lead to a variety of problems. Common causes of high catalytic converter temperatures include:

1. Overfueling: When too much fuel is injected into the engine, it can cause unburned fuel to enter the exhaust system and increase temperatures in the catalytic converter.

2. Ignition Timing Issues: If ignition timing is off, it can cause incomplete combustion and result in higher exhaust gas temperatures that are passed on to the catalytic converter.

3. Clogged Air Filter: A clogged air filter restricts airflow into an engine (unless you’re willing to consider learning how to hollow out a catalytic converter without removing it) and causes a lean air-fuel mixture that increases exhaust gas temperature and affects the performance of the catalytic converter.

4. Exhaust Restrictions: Any restrictions or blockages in an exhaust system will increase backpressure which leads to higher temperatures in both engine cylinders and downstream components such as a catalytic converter. This can be diagnosed by learning how to unblock a catalytic converter without removing it.

5. Engine Overheating: When an engine runs too hot due to a lack of coolant or other issues, this heat is transferred through its components including its exhaust system which can lead to increased catalyst temperature levels as well as damage or failure of other parts within it such as oxygen sensors or spark plugs.

The Benefits of Regularly Testing Your Catalytic Converter Temperature

The catalytic converter is an important component of a vehicle’s exhaust system. It helps to reduce the number of harmful pollutants released into the atmosphere by converting them into less harmful substances.

As such, it is essential that the catalytic converter operates at its optimal temperature to ensure maximum efficiency and performance (for more insight, check out our guide on whether can a bad catalytic converter cause a misfire). Regularly testing your catalytic converter temperature can help you identify any potential issues before they become more serious and costly to repair.

- Testing your catalytic converter temperature on a regular basis can help you detect any problems early on, allowing you to take corrective action before they become more serious or expensive to fix. This could include replacing worn-out parts or adjusting the air-fuel mixture to optimize performance. Additionally, regularly testing your catalytic converter temperature can also help you identify any underlying issues with other components of your vehicle’s exhaust system, such as clogged filters or faulty oxygen sensors.

- Regularly testing your catalytic converter temperature can also help improve fuel economy and reduce emissions from your vehicle. By ensuring that all components are operating at their optimal temperatures, you will be able to maximize fuel efficiency while reducing emissions levels significantly. This will not only benefit the environment but also save money on fuel costs over time as well as reduce wear and tear on other parts of the engine due to improved combustion efficiency.

- Finally, regularly testing your catalytic converter temperature can provide peace of mind knowing that all components are functioning correctly and efficiently without causing unnecessary damage or pollution levels in our environment. With regular maintenance checks and tests like this one, drivers can rest assured that their vehicles are running safely and efficiently while helping protect our planet for future generations too.

How to Diagnose and Repair a Faulty Catalytic Converter Temperature Sensor

Diagnosing and repairing a faulty catalytic converter temperature sensor can be a difficult task. However, with the right tools and knowledge, it is possible to diagnose and repair the issue. This article will provide an overview of how to diagnose and repair a faulty catalytic converter temperature sensor.

- First, it is important to understand what a catalytic converter temperature sensor does. The purpose of this device is to measure the temperature of the exhaust gases passing through the catalytic converter to ensure that they are within optimal operating temperatures for efficient operation. If the temperatures become too high or too low, then it can cause damage or reduce efficiency in your vehicle’s performance.

- To begin diagnosing a faulty catalytic converter temperature sensor, you will need an OBD-II scanner tool that can read diagnostic trouble codes (DTCs). Once you have connected your scanner tool to your vehicle’s OBD-II port, you should check for any DTCs related to your catalytic converter temperature sensor. If there are any codes present, then this indicates that there may be an issue with your device that needs further investigation.

- Next, you should inspect all wiring connections associated with your catalytic converter temperature sensor for any signs of corrosion or damage (not to mention, the signs of a bad catalytic converter) which could be causing issues with its operation. You should also check for any loose connections which could be causing intermittent faults in its operation as well as check all fuses associated with this device for correct functionality.

- If no faults are found during these steps then it may be necessary to replace the entire unit itself if it has failed completely due to age or wear and tear over time. It is important when replacing this part that you use one from a reputable manufacturer so as not to cause further issues down the line due to poor-quality parts being used in its construction or installation process.

- Finally, once everything has been checked over thoroughly and replaced where necessary; make sure that all wiring connections have been securely tightened before testing out your newly installed part by running some tests on it using an OBD-II scanner tool again if needed before putting everything back together again correctly so as not cause further issues down the line due incorrect installation procedures being followed during replacement process itself.

By following these steps carefully when diagnosing and repairing a faulty catalytic converter temperature sensor; you should find yourself able to resolve the most common issues related to this particular component without having sought professional help from a mechanic specialist who would otherwise charge more money than doing the job yourself at home.

The Impact of Exhaust System Modifications on Catalytic Converter Temperatures

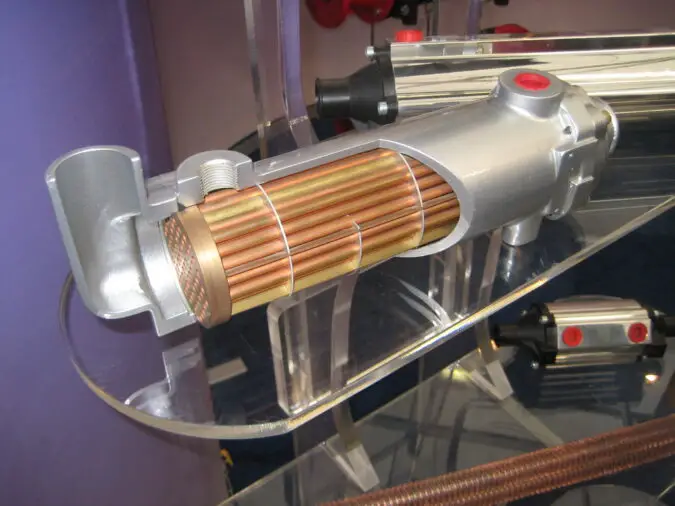

“Catalytic Converter” by Hiddenpower is licensed under CC BY-NC-SA 2.0

The exhaust system of a vehicle plays an important role in the performance and efficiency of the engine. Modifications to the exhaust system can have a significant impact on catalytic converter temperatures, which can affect the overall performance of the vehicle.

This article will discuss how modifications to an exhaust system can affect catalytic converter temperatures and what measures should be taken to ensure optimal performance.

- The primary purpose of a catalytic converter is to reduce harmful emissions from vehicles by converting them into less harmful substances. The temperature at which this conversion takes place is critical for optimal performance, as too low or too high temperatures can lead to the inefficient operation or even damage to the converter itself. As such, it is important that any modifications made to an exhaust system are done with care so as not to adversely affect catalytic converter temperatures.

- One way in which modifications may affect catalytic converter temperatures is through changes in backpressure within the exhaust system. Increasing backpressure by adding larger mufflers or other components may cause higher than normal operating temperatures due to increased resistance against gas flow through the pipes and out of the tailpipe. Conversely, reducing backpressure by removing components such as mufflers may result in lower-than-normal operating temperatures due to decreased resistance against gas flow through pipes and out of the tailpipe.

- Another way that modifications may affect catalytic converter temperature is through changes in an air-fuel ratio within engine cylinders during combustion cycles. If air-fuel ratios become too rich (too much fuel relative to air) then more heat will be generated during combustion cycles resulting in higher than normal operating temperatures for converters downstream from cylinders; conversely, if air-fuel ratios become too lean (too much air relative to fuel) then less heat will be generated during combustion cycles resulting in lower than the normal operating temperature for converters downstream from cylinders.

In order to ensure optimal operation when making modifications all components must be properly sized and installed according to their manufacturer’s specifications; this includes mufflers, pipes, headers, etc., as well as any other parts used within an exhaust system such as oxygen sensors or EGR valves.

Additionally, it is also important that proper tuning techniques are employed when adjusting engine parameters such as ignition timing or fuel injection settings so that correct air-fuel ratios are maintained throughout all engine operations. By following these steps one can help ensure proper operation while minimizing potential risks associated with excessive catalyst temperature levels.

Understanding the Relationship Between Engine Load and Catalyst Temperatures

The relationship between engine load and catalyst temperatures is an important factor to consider when optimizing the performance of a vehicle. Engine load is the amount of work that an engine performs, while catalyst temperature is the temperature at which a catalytic converter operates.

The two are closely related, as changes in engine load can affect the temperature of the catalytic converter. When an engine is running at low loads, such as during idle or light acceleration, it produces less exhaust gas and therefore requires less heat to be dissipated by the catalytic converter. As a result, catalyst temperatures remain relatively low under these conditions.

However, when an engine runs at higher loads for extended periods of time, such as during heavy acceleration or sustained high speeds on highways, more exhaust gas is produced and more heat must be dissipated by the catalytic converter. This causes catalyst temperatures to increase significantly under these conditions.

It is important to understand this relationship between engine load and catalyst temperatures to optimize vehicle performance and reduce emissions levels from vehicles equipped with catalytic converters.

For example, if a vehicle’s fuel economy decreases due to increased exhaust gas production from higher loads on its engines then reducing those loads can help improve fuel economy while also reducing emissions levels from its catalytic converters due to lower operating temperatures.

Additionally, understanding this relationship can help identify potential problems with a vehicle’s emission control system if it fails to operate properly under certain conditions due to excessive heat generated by its catalytic converters caused by high engine loads over extended periods of time.

In conclusion, understanding how changes in engine load affect catalyst temperatures can help optimize vehicle performance while also helping reduce emissions levels from vehicles equipped with catalytic converters.

Tips for Maintaining Optimal Catalyst Performance Through Proper Testing Procedures

1. Monitor the catalyst activity regularly to ensure that it is performing optimally. This can be done by testing the catalyst’s activity level, such as its conversion rate or selectivity, and comparing it to the expected performance.

2. Test for any changes in the physical properties of the catalyst, such as particle size or surface area, which could affect its performance.

3. Check for any signs of contamination or degradation of the catalyst material that could lead to a decrease in performance over time.

4. Perform regular maintenance on catalysts to ensure they are operating at peak efficiency and not being affected by external factors such as temperature or pressure changes in their environment.

5. Use analytical techniques such as X-ray diffraction (XRD) and scanning electron microscopy (SEM) to examine catalysts for signs of wear and tear that could reduce their effectiveness over time if left unchecked.

6. Utilize advanced technologies like spectroscopy and chromatography to measure reaction rates and identify potential problems with catalysts before they become serious issues that require costly repairs or replacements down the line.

Analyzing the Effects of Different Driving Conditions on Catalyst Performance

The performance of a catalyst is greatly affected by the driving conditions it is exposed to. To maximize the efficiency of a catalyst, it is important to understand how different driving conditions can affect its performance. This article will provide an overview of the effects that various driving conditions have on catalysts and how they can be optimized for maximum efficiency.

- Temperature is one of the most important factors in determining catalyst performance. As temperature increases, so does reaction rate, meaning that higher temperatures lead to increased activity from catalysts. However, too high a temperature can cause thermal degradation and reduce the effectiveness of catalysts over time. Therefore, it is important to maintain an optimal operating temperature range for maximum efficiency from a catalyst system.

- Another factor that affects catalyst performance is exhaust gas composition and flow rate. The presence of certain gases such as sulfur dioxide or nitrogen oxides can reduce the effectiveness of catalysts due to their ability to poison them over time. Additionally, changes in exhaust gas flow rate can also affect reaction rates within a catalyst system as higher flow rates lead to increased turbulence which reduces contact between reactants and active sites on catalytic surfaces leading to reduced activity levels overall.

- Finally, engine load also has an effect on catalyst performance as higher loads tend to increase exhaust temperatures which in turn leads to increased reaction rates within a system but also increases thermal degradation over time if not managed properly with cooling systems or other measures such as using multiple smaller reactors instead of one large reactor for better heat management capabilities overall.

In conclusion, understanding how different driving conditions affect catalyst performance allows us to optimize our systems for maximum efficiency while avoiding potential problems caused by excessive temperatures or poisoning from certain gases present in exhaust streams.

By taking into account all these factors when designing our systems we can ensure optimal operation under any given set of circumstances while minimizing any potential risks associated with improper operation or design choices.