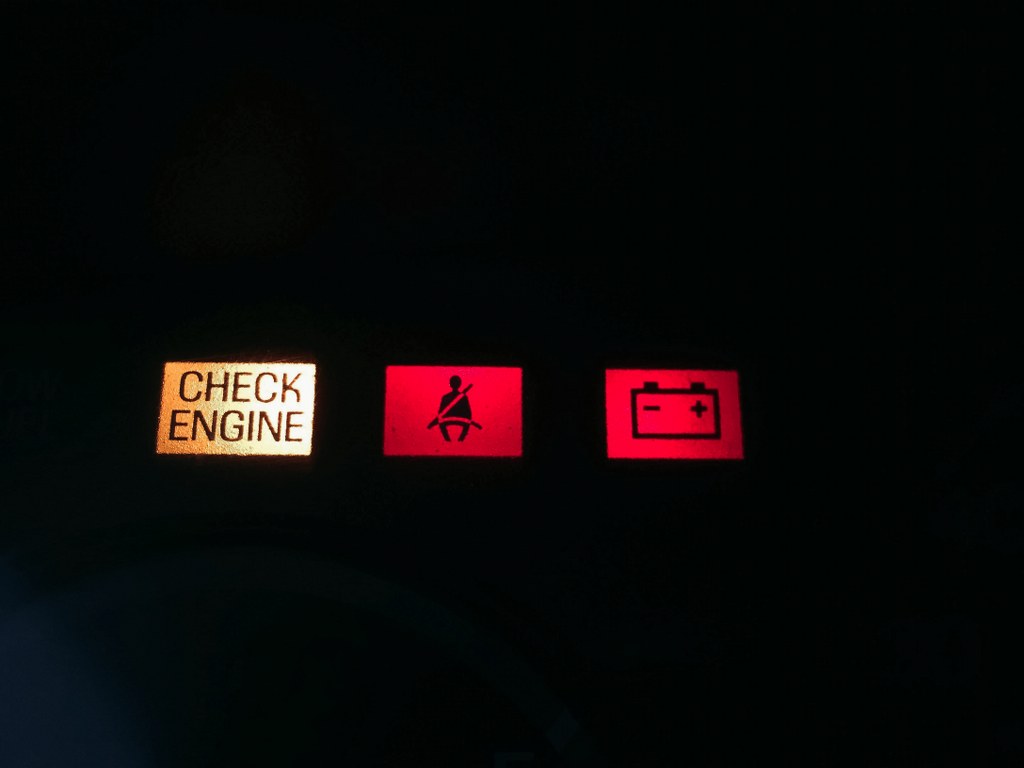

If you’re driving along and notice that the check engine light is blinking (instead of being off or on steadily), you should pull over immediately.

When you see a steady, continuous check engine light (that is, it’s on but isn’t blinking), you know there’s a potential fault with the engine. That being said, it’s not usually immediately dangerous. It would be best if you still pulled over to check the car out when it happens, regardless.

A blinking check engine light, however, is more serious. It’s basically the normal CEL (check engine light), but a more extreme version, warning you to stop the car – right now. If the light comes on and blinks, you’ll need to pull over and call for assistance, taking the car straight for diagnosis and repairs.

In this article, I’ll be explaining some of the leading causes of a blinking checking engine light.

Check Engine Light Blinking Causes

Several things can cause a blinking check engine light.

It boils down to there being a severe misfire issue within the engine.

This is why you have to shut your car off as quickly as possible once you’ve seen the blinking light. The longer it’s on, the greater the risk of catastrophic engine damage and, consequently, the greater the risk of damage to you, too. Engine repairs can be extremely costly, so the faster you can turn everything off, the more money you could save.

For the purposes of this article, I’ve divided some of the main causes up into sections: ignition, exhaust/emissions, timing (which refers to spark timing, but I’ve also included valve timing and fuel injector timing here), and compression.

There will undoubtedly be other causes that I haven’t mentioned here. Although I hope this list helps you get a good grasp of what might be wrong, it’s no substitute for a skilled mechanic and OBD code reader.

Ignition – Check Engine Light Blinking

The ignition system within your car is what “ignites” the fuel. In a gasoline-powered vehicle, these are the spark plugs and ignition coils. Older cars also utilize distributors.

The video you see below from Automotive Basics shows an old-fashioned distributor-style ignition system. Most modern cars work differently, but it’s suitable for understanding the basics.

Some modern cars still use distributor caps, but they’re fast fading out of use. Nowadays, manufacturers build cars with timing controlled by toothed timing wheels. Rather than one ignition coil, each cylinder has a separate one. The ECU is in control of when these coils fire.

To summarize the above, the ignition coil is a basic electrical transformer (high school physics, anyone?). It consists of a primary winding and a secondary winding. The primary winding receives current from the car’s electrical system, and the difference in how many “coils” around the core there are either increases or decreases the voltage.

(According to Ohm’s Law, it does the opposite thing to the current.)

In the case of a car, the voltage is increased – dramatically. It’s usually between 12,000 and 25,000 Volts. The spark plug then converts this voltage into, you guessed it, a spark. This spark then ignites the fuel/air mixture within the cylinder and triggers the power phase of the engine’s cycle.

Coming back to considering how this affects your blinking check engine light, if something goes wrong with this system, it’ll cause a misfire.

Spark Plugs

If there’s a fault with the ignition system, it’s almost certainly down to either a spark plug or ignition coil. There’s the good news. Unless you have a V-engine, spark plugs are usually one of the most straightforward maintenance tasks possible.

Spark plugs are a regular maintenance item. They aren’t expected to last long. Like brakes and tires (across the axles, at least), it’s worth replacing all of them at once. That way, you know they’re all in good condition. If, six months down the line, another misfire develops, you can remove the plugs and see if any are in worse shape than the others. Since they all went in simultaneously, you have a good reference point to work out which cylinder the problem might be coming from.

Following on from that, this is probably as good a time as any to replace all your spark plugs. Note their condition when you take them out, as this may indicate where the problem lies.

If you really wanted to be sure, you could check the spark plugs one by one using a multimeter. Doing this would show you if any of them aren’t conducting electricity and therefore not sparking.

Ignition Coils

Moving on, let’s think about ignition coils.

These are considerably more expensive than sparks plugs, and so you should consider onboard diagnostics – OBD. It’s usually not worth it to replace all of them at once unless, like my 2005 Vauxhall Corsa C, they come in a “module”. That is, they’re all sort of lined up in one component. You can’t separate them from each other.

I’ll present some more thoughts on OBD towards the end of this article.

Using the OBD II port, a code reader may be able to tell you which cylinder is presenting the misfire. It may also tell you that something else, entirely, is the source of the issue.

Once you’ve identified the cylinder, remove the ignition coil and use a multimeter to test it. The video seen below shows how to do this. It’s based on a motorcycle or ATV engine, but the concept is exactly the same.

Hopefully, there’s only a problem with one cylinder. If you identify a malfunctioning ignition coil, replace it and get a professional to wipe the car’s stored codes. When you start the engine, the check engine light shouldn’t even be on, let alone blink.

Distributor Cap

Although this is less common nowadays, with fewer and fewer cars having distributor systems, you may be driving a car with one.

When there’s only a misfire in one cylinder, the usual cause is a buildup of gunk between the rotor and the terminals that it spins past. You might also find a broken contact terminal. It should be fairly simple – but fiddly – to take apart and clean using parts cleaner.

Exhaust And Emissions – Check Engine Light Blinking

The exhaust is an integral part of your car’s system. Nowadays, it’s so much more than just a metal tube.

Your exhaust contains at least one oxygen sensor (and probably two) and a catalytic converter (again, at least one). The EGR system – exhaust gas recirculation – is also prevalent in new cars. While EGR systems aren’t required, virtually all manufacturers use them to meet emissions requirements.

These, collectively, function in two main ways:

- The oxygen sensors (also known as lambda sensors) measure the amount of oxygen in the exhaust gases as they leave the engine and pass through the exhaust and cat. The ECU then uses this information to control the EGR system. It opens the EGR valve, depending on the amount of oxygen it detects. The exhaust gases are then “recirculated” back through the combustion chamber. Because of this, a much more significant percentage of fuel gets burnt, leading to fewer hydrocarbons clogging up the catalytic converter or escaping into the atmosphere. A nice side effect is that the engine also becomes more efficient, often using over 10% less fuel.

- They reduce the car’s environmental impact. The “cat” converts toxic nitrogen oxides and hydrocarbons into carbon dioxide and water. Yes, carbon dioxide is still a major problem, but we’d be in a much worse state without the catalytic converter. For now, it’s the lesser of two evils, although it certainly needs to be addressed very soon. The EGR system also reduces environmental pollutants significantly. It does this by essentially re-burning anything that didn’t wholly combust initially.

If anything goes wrong with these systems, it’s usually an indication of something going wrong in the engine. The problem stemming from the engine leads to damage to these systems.

Let’s look at them in more detail.

Oxygen Sensors

You usually find one oxygen sensor before the catalytic converter and one after it. The ECU then analyzes the information from these sensors to determine how far open the EGR valve should be and whether the catalytic converter is working.

The oxygen sensors are also used in conjunction with the fuel injectors to determine how rich or lean the air/fuel mixture is. We’ll think about the fuel injectors in one of the following sections.

If an oxygen sensor were to stop working, the ECU would be unable to compute all of the above information. The EGR system would start playing up, the fuel injection system wouldn’t know quite what was going on, and there would be no way to tell whether or not the cat was working.

More often than not, the cause of an emissions-related blinking check engine light is an oxygen sensor. In actual fact, there’s no problem with the cat or EGR system at all.

Most of the time, oxygen sensors fail due to a buildup of soot (hydrocarbons – unburnt fuel). Since they’re exposed to this all the time – it’s their job – this is to be expected. Despite this, oxygen sensors aren’t usually listed as service items and are generally only replaced when they fail.

I’d recommend using a multimeter to check whether or not your oxygen sensor is working before replacing it. Take a look at this video – I’d recommend watching it all the way through. It’s a great, quick example of how to test an oxygen sensor.

Some cars with advanced OBD settings may be able to tell you that there’s a problem with the oxygen sensor by itself. In that case, great! In my opinion, though, it’s still worth checking the sensor with a multimeter, just to make sure that the ECU hasn’t got confused and misdiagnosed the issue.

If an oxygen sensor becomes clogged up due to hydrocarbons, it’s an indication of incomplete combustion in at least one cylinder. This needs further investigation.

Catalytic Converter

Unfortunately, after spark plugs, ignition coils, and oxygen sensors, the catalytic converter is the next most likely cause of your blinking check engine light.

It’s the big one – in most cases, by far the most expensive on this list, aside from compression issues. To look at the ins and outs of what you might have to pay, check out this article. The costs vary massively from car to car, but a nice round figure of $1,000+ is probably a decent, vague estimate.

The ECU uses the oxygen sensors to work out if the catalytic converter is working or not. One sensor goes before the cat, the other after. The difference between these readings gives an indication as to how effectively the cat is working.

Sometimes, the car’s OBD system might tell you that there’s a problem with the cat when, in fact, it’s an oxygen sensor at fault. Don’t fall for this! Make sure you follow the previous section’s steps to ensure that you only replace the catalytic converter if it’s definitely stopped working. It’s not a nice thing to have to do to your wallet unless absolutely necessary.

If a catalytic converter fails, it can cause a blinking check engine light because it’s a critical emissions item. Legally, your car needs to have one (depending on its age).

Replacing the catalytic converter might make your blinking check engine light turn off. However, the cat has probably only stopped working due to a deeper fault within the engine. Like with the oxygen sensors, you’ll have to investigate this more deeply to find the true cause.

Timing – Check Engine Light Blinking

The timing system relates to the timing of the sparks, as we’ve briefly touched on in one of the previous sections.

The valves and the fuel injectors also rely on their own “timing” systems, although they aren’t what you’d usually be referring to.

Problems with your timing can cause misfires and other types of damage to your engine. As a result, your check engine light may come on and start blinking.

Spark Timing

If the spark plug isn’t firing at the right time – either due to a distributor cap, timing gear, or another electronic issue – the fuel won’t be fully burnt, if at all. As a result, the engine’s power stroke is diminished or neglected completely, and you’ll get unburnt hydrocarbon chains forced down the exhaust, clogging up the cat and polluting the atmosphere.

You’ll need to take apart your engine to find the fault here. Use an OBD II code reader to read any codes.

Valve Timing

The valves in your engine are responsible for the intake and exhaust phases of the four-stroke cycle.

The intake valves bring air and fuel (or just air, if the engine has direct injection) into the combustion chamber. On the other hand, exhaust valves open to remove most of the leftover gases after the spark plug ignites the chamber’s contents.

The camshaft controls them. There are various designs of a camshaft, but, in general, it has lobes on it that force the valves down into the engine. This motion creates space for air/fuel to come in and exhaust gases to leave. The crankshaft connects to the camshaft via a timing chain or timing belt.

For every engine, there’s an optimal moment for the valves to open and close. That’s why timing chains have to be installed so accurately.

Sometimes, it’s possible for the valve timing to advance or retard. That is, be too early or be too late. If this happens, the engine won’t be working efficiently. It’ll also be under extra strain.

This may cause your check engine light to come on and blink.

The most likely culprit here is the VVT system – variable valve timing. There are more possible setups for this system than I can list. Check out the video below for a quick explanation of how it all works (in general).

You may also have a problem with the timing chain or belt.

This kind of work is best carried out by a professional. Making a mistake here could be highly costly and virtually destroy your engine.

Fuel Injection Timing

Here’s Engineering Explained to walk you through the basics of direct injection and port injection.

For the purposes of this article, I’ll keep it simple.

In engines – especially those with direct injection – if the fuel isn’t pumped in at exactly the right moment, it leads to incomplete combustion and a buildup of gunk and soot. Your engine will also be low on power and have decreased fuel economy.

If the fuel injectors are pushing out the fuel at the wrong moment – be that too late or too early – you are likely to develop a misfire. Like everything else we’ve looked at so far, this issue could lead to more serious problems down the road. The ultimate issue would be a catalytic converter that stops working.

Depending on your vehicle and your mechanical know-how, you may be able to diagnose and replace your fuel injectors yourself.

Compression – Check Engine Light Blinking

If an OBD scan reveals problems with cylinder compression, it’s not good. The ultimate cause could be one of a few things, but, long story short, there’s a hole somewhere there shouldn’t be one. This means that pressure is escaping where it shouldn’t. As a result, your car has considerably less power.

You can test your car’s cylinder compression with basic kits that you find online. For a high-quality one, you’ll probably have to pay about $60 to $80. Budget models are also available for around $20 to $30.

Your problems, if they are here, will probably boil down to one of these three things:

- piston rings,

- valves or valve seats,

- or a blown head gasket.

The piston rings seal the area above the piston from the area below it, creating pressure in the combustion chamber. They also prevent oil from getting into the chamber and being burnt. If one has broken or corroded, it won’t be keeping the pressure within the cylinder properly.

In the same way, the valves seal the cylinder at the top. The valves sit snugly into the valve seats and shouldn’t allow anything past them (unless they’re open, of course). If there’s any corrosion on either the valves or the seats, they might not seal the chamber properly.

The head gasket sits between the cylinder head and block. Its principal function is to keep the two parts of the engine sitting close together and to prevent oil and coolant from mixing or getting in the combustion chamber. When the head gasket “blows”, it can’t do this job any more.

Sometimes, you might even get a literal hole in the side of the cylinder wall. This situation is much rarer, but I’ve seen it a couple of times. If this happens, you’ll need a new engine, and it might make more financial sense to scrap the car.

Any of these situations could lead to the check engine light blinking, as they’re dangerous to drive with. They could also lead to irreparable damage to the engine, and so, for both reasons, you’ll need to get them fixed as soon as possible.

A Few Thoughts On OBD II

When using OBD, I would recommend taking your car to a shop and getting someone to do it professionally. Why? Although it’s tempting to buy a $10 plastic piece of junk from Amazon, I have heard rare stories of these readers completely wiping cars’ ECUs. Thus, your $10 “bargain” turns into a $2,000+ reprogramming job.

The OBD code readers that mechanics use often cost many thousands of dollars. (Incidentally, this is why you might be charged for its use.) If the cheaper models were any good, they’d get them, so don’t fall into the marketing trap of a popup advert.

That being said, there are some great cheap ones you can get your hands on. Do your market research and make sure you trust the producer, and everything should be just fine.

An OBD II code reader is a very useful tool and it’s definitely worth having one around, available to use whenever you need it.

Check Engine Light Blinking – Facts You Need to Know

- A flashing check engine light should not be ignored, as driving with a compromised engine can cause serious damage to different engine components, and might even lead to more serious and costly problems such as a blown catalytic converter.

- Ignoring a check engine light might result in paying thousands of dollars more than necessary for long-term damage incurred on your vehicle.

- The most common cause of a flashing check engine light is usually an engine misfire.

- An engine misfire might occur due to many reasons such as ignition problems, fuel mixture imbalances, and low compression.

- Regular maintenance and replacement of ignition parts such as spark plugs and ignition coils can prevent engine misfires.

- Fuel system components need to be thoroughly checked to address issues caused by fuel mixture imbalances.

- Loss of pressure in cylinders due to leaks in the head gasket, piston holes, or compromised valves or timing belts might result in slow acceleration, low power, or jerky running of the car.

- Signs of engine misfiring include shaking or vibrations, jerky acceleration, losing power, strange sounds from the engine, and the smell of gas.

- If you notice any of the signs of engine misfiring, it’s time to get your car checked out.

- By taking care of a flashing check engine light quickly, you might be saving yourself heaps of time and energy in the long run.

Conclusion

If the check engine turns on, you should certainly be wary, but it’s probably safe to continue until you get to an auto shop or somewhere safe for repairs.

However, if it turns on and starts blinking, it indicates a severe issue. You need to pull over immediately and call for help. If there’s nowhere to stop, be very gentle with the car but nurse it along until you get somewhere to stop without being a hazard.

You shouldn’t ever ignore a blinking check engine light. It’ll only lead to further damage, mounting costs, and increasing risks to your safety.

As well as working on everything we’ve looked at in this article, you could also do the following:

- Use Cataclean, or other similar products, to help flush the engine through. These products and additives help to remove dirt, metal shards, and other contaminants, leaving you with a smoother-running engine.

- Have the car serviced – just a basic oil and filters service will do, although you may also want to change the spark plugs and ignition coil(s).

- Use some premium fuel – the longer the hydrocarbon chains, the better they are for your engine. Look at the numbers on the pumps. Yes, they often directly relate to the price per gallon, but if you want to keep your car in shipshape condition, that’s a necessary evil.

There are many things we haven’t talked about here, too.

I didn’t go into much detail on the EGR valve or system as a whole. The MAF sensor is also commonly known to cause a blinking check engine light. Some people have to replace the thermostat or otherwise work on the coolant system. You may have a serious oil pressure problem.

Finally, the most random of them all: the gas cap. Sometimes, the cap becomes loose. Sometimes, it’s fine but the engine thinks it’s loose. You might see a blinking check engine light if this happens. Take your car down to the local shop and get a mechanic to check it out. After all that, you might simply need a new gas cap.

Madness.

Basically, the possibilities are almost endless, particularly as modern cars are pretty much massive computers. If anything to do with the engine – anything at all – goes wrong, it could trigger that light.

That’s why, unless you’re experienced, this kind of thing is often best left to a professional mechanic.

Thanks for reading!