The engine is one of the heaviest and most important parts of any vehicle. The average vehicle engine weighs about 400 pounds. Trucks and other larger vehicles have engines that weigh a lot more than that. This is why you need to have the engine mounts in good condition to avoid any problems when you are on the road. Eventually, the engine mounts will break, and therefore you have to pay the full motor mount replacement cost.

Think of the torque, power, and vibrations generated by the engine as it runs; then, you will agree that the motor mounts live a difficult life. If all these vibrations were to be transferred to the body or chassis of the vehicle, it would make driving unbearable. Motor mounts don’t get a lot of attention until they are broken, play a vital role in enhancing the driving experience and performance of your car.

This guide will review in-depth how the engine mounts work, symptoms of a faulty motor mount, causes of worn-out motor mounts, how you can inspect and replace the motor mounts, and the full replacement costs. Motor replacement costs, of course, will vary across different types of motor mount types, arrangements, and materials. The time it takes to replace the motor mounts, and the difficulty accessing them will also determine the labor cost.

- What Is It?

- How It Works

- Symptoms Of A Bad Mount

- How It Affects Transmission

- Diagnosis

- Why Do They Break?

- Types

- Replacement Cost

- DIY

- Conclusion

What Is A Motor Mount?

Before delving into how the motor mount works, it’s imperative first to understand what a motor mount is. A motor mount, also known as an engine mount, is simply the part that secures your car’s engine to its chassis. Typically, the transmission and engine are securely bolted together and held steadily by three to five mounts. The mounts holding the transmission in place are known as transmission mounts, while the rest are motor mounts.

How It Works (Prior To A Motor Mount Replacement Cost)

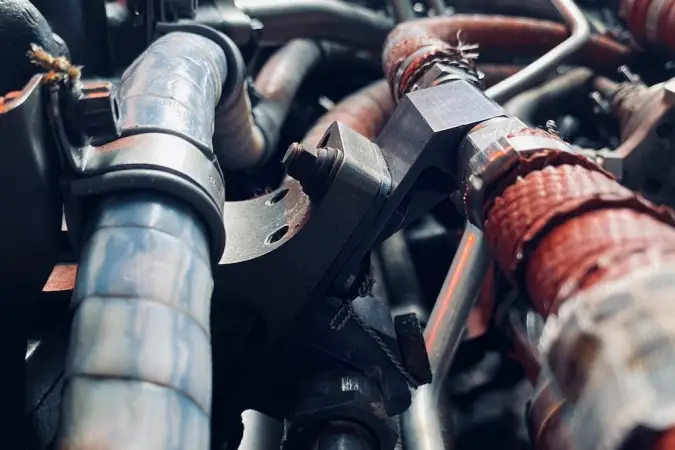

One part of the engine mount holds the engine in most cars, while another part is firmly bolted to the car’s frame or body. In this case, the motor mount is a rubber bushing with a bolt hole in the middle to connect the two components. Most car engines typically have a motor mount in each corner. Although this seems quite flimsy, don’t worry; these mounts are built tough enough to take the punishment.

If you have ever seen an unmounted engine running, you must have noticed the intense vibrations and violent shaking. Have you ever wondered why little to none of these vibrations are felt in the car as a passenger or when you are behind the wheel? At least with a well-maintained or newer vehicle. All this is possible thanks to the motor mounts that make driving your car as relaxing and smooth as possible.

Motor mounts are designed like shock absorbers to absorb all the vibrations of the engine. They do this so well that you can no longer feel the vibrations or torque generated by the engine. Even with more powerful engines, the vibrations and shaking are reduced to a point they are not noticeable in the car’s cabin.

Motor mounts come in different sizes and shapes, but they all have the same function of linking the engine to the rest of the car. The metal part of the motor mount is tasked with withstanding the weight of the motor and holding it in place even as it exerts extreme torque. The rubber part reduces or absorbs the vibrations. By now, it should be clear that some symptoms will occur if the motor mounts fail.

Symptoms For A Motor Mount Replacement Cost

Although motor mounts are built to take heavy punishment from the engine, they will not last forever. Luckily, you are likely to immediately notice when one of the strategically located motor mounts breaks down. Although it does not pose any safety hazard when you first notice the warning signs, the trembling and loud noises can make it harder to concentrate on the road. Here are some of the top signs of a bad or faulty motor mount.

1. Loud Noises From The Engine Bay

A strange knocking sound is the most common sign of a broken motor mount. Since the engine is held steadily by the motor mount, the engine moves around in the frame when one of the mounts breaks. As the motor vibrates and shakes, it will make clanking and knocking noises that can tell if the motor mounts are broken. The noise is generated as the engine block hits the broken mount or other components under the hood.

As stated earlier, one of the engine mounts’ primary functions is reducing the engine’s noise. Therefore, if the engine becomes an auditory nuisance, there is something wrong with the motor mounts. You can especially tell this if the noise produced is a loud rattling when you hit hard against a pothole or bump. If you notice such noise, contact your mechanic as soon as possible.

2. Intense Vibrations

Another tell-tale sign that you have bad or faulty motor mounts is a violent vibration when the engine is running. The vibrations may intensify when you rev or accelerate the vehicle. Another primary function of a well-functioning motor mount is to dampen the vibrations of an ignited engine. If you start your engine and the vibrations can be felt throughout the frame or body of the car, this is a key sign that one or more motor mounts are worn out.

When a motor mount is worn out or broken, it loses or weakens its anti-vibration properties. When the vibration is transferred to the metal panels of the car’s body, it can present as noise. Therefore, you may even tell there are vibrations even without touching the vehicle. If the motor mount breaks when you are behind the wheel, you will notice a sudden increase in vibration, especially on the steering wheel.

3. Misaligned Engine

The motor mounts are also utilized for the proper alignment of the engine in a car’s frame. This increases the efficiency and performance of the vehicle. The engine must remain in the same position it was installed. When it shifts, even a little, it can cause deterioration in the car’s performance. By looking closely at the engine’s position, it is relatively easy to tell if it is skewed. This is the first sign that a damaged motor mount is genuinely hazardous.

Also, if you look under the hood of your car and notice that the engine is tilted to one side, it can be a sign of a faulty motor mount. Typically, most engines are designed to sit upright in the engine bay. However, if your engine is slightly tilted, it does not necessarily conclude that you have a broken motor mount. Some carmakers fit their engines tilted if you are not sure if this symptom, google the model of your car to see some pictures of how the engine should sit.

4. Engine Movement

When a motor mount breaks or wears out, the engine becomes loose. This leaves the engine susceptible to movement in the engine bay. You may notice this is if you leave the car on idle and open the hood to observe the engine as it runs. If the engine jerks around as it runs, it is clear that one of the mounts is broken or damaged. When functioning properly, the motor mounts hold the motor firmly to the rest of the car.

Even when only one of the multiple mounts is damaged, the engine will show some backward, sideways, or forward movements. Although this movement occurs in the engine area, it poses a safety hazard to the driver and passengers in the cabin. These engine movements are often accompanied by knocking sounds. Much of the movement is only noticeable when you are accelerating the vehicle.

5. Broken Hoses And Belts

The engine utilizes belts and hoses to transfer drive power to other components and accessories in the engine bay. For example, the serpentine belt transfers power to other parts such as the AC and alternator. These belts are usually tight-fit, and the belt tensioner eliminates any clearance. Therefore, if the engine happens to move, even over a short distance, the belts and hoses are most likely to break.

If you have a broken belt, it is most likely you have a broken motor mount. The belts and hoses are some of the fragile components around the engine. These fragile components break easily when the engine is displaced. Most belts are meant to operate on perfectly aligned engines. If your engine is misaligned, it will likely break the hoses and belts.

How Does A Bad Motor Mount Affect The Transmission?

The transmission is integral to the workability of your car. In addition to the symptoms mentioned above, a bad motor mount also affects the transmission. One of the biggest problems is that the engine gains momentum before slamming to a halt on the broken motor mount. This creates a hammering effect. The universal and constant velocity joints are the first components to suffer. This is because they are delicate and cannot handle such a force.

Although the CV and U- joint will fail before the hammering effect damages the transaxle, there is always a possibility of damage to the transmission. Front-drive vehicles are especially prone to having the CV-joint axle shafts disengaged from the differential when the engine squirms too much. The retainer used on many axle shafts can break and end up in the differential gears. Even if it does not break, the shoving motion of the C-clip can damage the axle shaft splines and the differential output splines.

Diagnosis For A Motor Mount Replacement Cost

Engine or transmission damage via faulty motor mounts is not likely to be sudden unless the whole engine or transmission becomes too loose and falls of the chassis. However, faulty or worn-out motor mounts will eventually lead to a host of drivetrain, chassis, engine, and transmission problems. If you have ascertained that you have a bad motor mount, don’t ignore it, have it fixed before it escalates to more expensive ancillary repairs.

If your car shows one or two symptoms of a bad motor mount, but you are still not convinced, there are several ways of diagnosing a car for faulty motor mounts. Fortunately, it does not take sophisticated tools and know-how to diagnose this issue. With a few simple tools like a pry bar or torch, you can confirm if a bad motor mount causes your problems. Here’s how;

Step 1: Visual Inspection

The metal part of the motor mount changes its appearance over time. Open your hood and visually inspect the metal part for any obvious corrosion or cracks. If you discover any deformities, it indicates that the mount is damaged. A crack limits the motor mount’s efficiency. For the engine mounts to remain effective, they rely on their form and shape. If you notice any significant changes to these two, consider replacing the affected mount.

Step 2: Pry The Motor Mount

Another great way of diagnosing a broken motor mount is by using a pry bar to check for excessive engine movement. The engine is meant to stay put even when it generates extreme torque. Therefore, it should not budge when pried. Place the pry bar where the motor mount supports the engine. Push or pull the pry bar around to check or any engine movements. This will also show any signs of rubber cracks or dry rot on the motor mount.

Step 3: Check For Leaks

Some motor mounts have hydraulic fluid to absorb and dampen the engine vibrations. If the hydraulic fluid leaks out of the motor mount, it weakens the dampening properties, and you may experience bad motor mount symptoms. It is therefore important to check for leaks during regular maintenance. If other components are leaking oil and it happens to get to the rubber of the motor mount, it can compromise the integrity of the rubber. Start by fixing any oil leaks before installing any new motor mounts.

Why Worry About A Motor Mount Replacement Cost?

1. Aging

This is the most common reason for faulty motor mounts. As the rubber on the motor mount ages, it becomes susceptible to dry rot. This is usually due to the harsh temperature conditions in the engine compartment. This does not happen suddenly and takes several years of use. When the harsh temperature conditions are combined with the stress put on the mounts by the engine’s weight, they wear out the rubber part of the motor mount. Hydraulic mounts break for the same reason.

2. Defects

Although very rare, it is still possible to have a defective motor mount. This will cause the motor mount to break sooner than expected. A defective motor mount will not show any signs of wear or tear. It might even break immediately or may last a few trips before breaking. The sudden failure may bring along severe consequences such as engine or transmission damage. A faulty motor mount will break even with normal driving.

3. Abuse

Motor mounts are constantly under stress every time you start your vehicle or shift gears. The number of vibrations, shaking, and torque exerted on the mounts by the engine each time it revs is extreme. The motor mounts are stressed further when you race at the track or drive aggressively on the road. When you step on the gas pedal, the engine generates torque that moves it, stressing the mounts holding it in place. Under harsher stress, the engine mounts will break even if they are not suffering dry rot or mold.

Types Of Mounts For A Motor Mount Replacement Cost

1. Hydraulic Motor Mounts

Also known as hydro engine mounts, motor mounts use a hydraulic gel or liquid to absorb the engine vibrations. The hydraulic motor mounts are specifically designed to dampen the engine vibrations before they sneak into the chassis of the vehicle. Hydraulic motors are particularly common because they can be tuned for better performance. Therefore, they find application over a wider range of conditions. Hydro mounts are more expensive than the standard rubber engine mounts.

2. Solid Rubber Motor Mounts

These are made of solid rubber and are bolted to the chassis and engine using steel-backed plates. Solid rubber motor mounts offer great flexibility and effectively absorb the shocks that would be transferred to the body or frame. This type of motor mount is a great option for holding the engine steadily, dampening the vibrations, and minimizing the noise at a relatively lower cost. However, one downside is that they tend to wear out quickly when installed improperly or put under heavy load.

3. Electronic Motor Mounts

Electronic motor mounts are designed to electronically vary the damping and stiffness characteristics of the motor mount. These electronically-controlled mounts are mostly found on late-model import cars. Altering the stiffness of the important is important for canceling out harmonics at different engine loads and speeds. The stiffness is altered using a vacuum actuator. Some models even generate their counter vibrations to offset those generated by the engine.

4. Metal Mounts

As the name suggests, these are motor mounts that do not have any polyurethane or rubber parts. A metal mount is made of metal parts only. Sure, they have little to no vibration and noise dampening properties. However, they compensate for this drawback by allowing maximum power transfer from the engine to the wheels. They are only used in race cars that often compromise comfort for performance.

5. Polyurethane Mounts

PU motor mounts offer a longer-lasting alternative to transmission mounts. Polyurethane material exhibits the characteristics of rigidity and flexibility. Therefore, these mounts provide the benefits of solid steel mounts and rubber mounts combined. Although they come with a higher price tag than the rubber alternatives, PU motor mounts provide enhanced performance and comfort. One major drawback is that polyurethane does not handle high-temperature conditions as well as rubber or metal.

What Is The Motor Mount Replacement Cost?

There are a variety of factors that determine how much you can pay for a motor mount replacement. The two most significant factors are the model of your car and where you take it for motor replacement. Smaller auto shops always tend to charge far less than what the dealerships charge. However, when choosing where to take your car for repairs, the biggest consideration should be having the job done correctly. Take your car to someone you trust to do the job.

1. Part Costs For A Motor Mount

Although they vary in type and shape, motor mounts themselves are cheap. Typically, a motor mount cost ranges between $40 and $200 depending on the size and model of the vehicle. Larger vehicles have bigger engines which require large motor mounts and hence a higher cost. Fortunately, you don’t have to replace all the motor mounts when one gets damaged. Unless they all show signs of wear. Generally, most motor mounts are made to last five to seven years. Save yourself some headache by replacing them all at once.

2. Labor Cost To Replace The Motor Mount

Although the motor mounts aren’t expensive, you will be lucky to get a mechanic to do the job for under $200. Depending on the vehicle’s model and which repair shop you take it for replacement, you may end up spending around $400 on labor alone. Some motor mounts are easy to access, while others require components to be removed. The difficulty of accessing the motor mount is the primary reason for variation in costs.

However, if a broken or worn-out motor mount is being replaced, the cost of getting the others done at the same time will be relatively minimal. This is because all that has to be done is move the jack to different mount locations to lift the engine’s weight off the mount and replace it.

3. Total Costs For Replacing A Faulty Motor Mount

Adding up the part and labor costs will cost you between $240 and $600 to have your motor mounts replaced. This is typically the cost of replacing only one of the multiple motor mounts. As stated earlier, if you choose to have all the motor mounts in your car replaced simultaneously, you can expect to pay less. In this case, it will cost you between $360 and $1200 to replace four mounts. This includes all the added expenses, such as the part costs.

Replacing The Motor Mounts On Your Own – Motor Mount Replacement Cost

If you have the right tools and basic car knowledge, motor mount replacement isn’t as complicated as it may seem at first. The hard part is lifting the engine of the mount being replaced. This should be a relatively straightforward job if you are armed with the right lifts and proper jack stands. By replacing the motor mounts yourself, you can make some big savings on labor costs. Even if you know what you are doing, it will still take some effort and time to get the job done.

However, if you have little to no mechanical know-how and experience, it is better to leave the job to a pro. Lifting heavy car parts like the engine poses a risk of falling and causing serious injury or death. Another important tip for DIYing this job is to use a wooden block on the jack when lifting the engine. This prevents the jack from damaging the oil pan of the vehicle.

Motor Mounts: Facts You Need to Know

- Motor mounts, also known as engine mounts, secure the engine in the engine bay and prevent excessive movement. A worn-out engine mount can cause a variety of issues, so it’s essential to know when to replace them.

- There are five common types of motor mounts: solid rubber, metal, polyurethane, hydraulic, and electronic. Each has unique benefits and drawbacks in terms of durability, vibration damping, and cost.

- Prices for motor mounts vary depending on the make and model of the vehicle and the complexity of the mount. A simple steel or rubber mount can cost between $10 and $150, while hydraulic or active motor mounts can cost between $50 and $200 or more. Labor costs range from $100 to $450 per mount, depending on accessibility.

- Symptoms of a bad motor mount are usually related to excessive vibrations, such as increased vibrations when idling or driving, thudding or lurching when starting or stopping the engine, or odd impact noises from the engine compartment.

- It’s generally worth replacing worn-out motor mounts, even in older vehicles, as a preventative maintenance measure to avoid more significant issues and expenses down the road.

- To replace an engine mount, start by removing the negative wire from the battery and safely supporting the engine. Depending on which mount you’re replacing, you may need to use a jack to elevate the car and remove bolts attaching the engine to the motor mount and the motor mount to the chassis. Some vehicles may require removing parts of the subframe or other engine bay components.

- If you’re experiencing symptoms of a bad motor mount, investigate to ensure it’s not a misfiring cylinder causing the vibrations.

- A solid rubber motor mount provides middle-of-the-pack vibration damping, while metal mounts are extremely durable but transmit vibrations readily. Polyurethane motor mounts are stiffer than rubber but less resistant to heat than steel. Hydraulic motor mounts can be tuned to attenuate specific frequencies but are more complex and expensive to manufacture than solid rubber mounts.

- Electronic engine mounts, also known as active engine mounts, use positioning sensors to monitor engine position, RPMs, speed, and other factors to tailor damping force.

- A bad motor mount can cause damage to various systems in the engine bay and should be replaced promptly to avoid further problems.

Conclusion – Motor Mount Replacement Cost

Although you don’t see them in action every day, you mustn’t take the motor mounts for granted. While they quietly do the dirty job in the background, you will miss the motor mount’s dependability once the car starts shuddering every time you shift the gears. Motor mounts are integral to the performance of your car’s engine and should be replaced immediately you notice any symptoms of failure. It may seem a small problem at first, but it can quickly and easily morph into a more expensive repair.